The year begins with a production of Christopher

Each bear's German glass eyes are inserted by hand

A group of bears following their final airbrushing

Christopher's sunflower is made of molded felt and alpaca plush

The vintage-style cotton romper is buttoned on

A group of completed bears await boxing

Each Christopher is packaged with his own sunflower!

On the felt arms, the individual fingers are precisely sewn!

The snowsuits are sewn of felt and wool plush

The matching hats are turned inside out

Special procedures are used to create the tiny covered buttons

Finishing work on the felt snowsuits

The tiny felt-covered buttons are added

The dolls are dressed before the heads are attached!

Meanwhile, the heads are molded, painted and wigged

The leather boots are hand-cobbled

The soles and heels are attached

In another area, work begins on the wooden sled

The parts are created with skill and precision

A group of sleds await their bottom runners

Each doll is dressed snugly for wintertime play!

The dolls are placed in their deluxe presentation boxes

The mohair wigs are styled on the Spring dolls

Spring's dress is sewn of fine Italian organdy

Tiny silk buds are added to the waistband

The felt bonnets are sewn together

Each bonnet is blocked and finished by hand

The tiny felt bunnies will be held by Spring

Each bunny is delicately airbrushed

A tray of completed miniature toy bunnies

Trays of completed Spring dolls await boxing

Each doll receives her Springtime bunny

The dolls are beautifully packaged

The parts for Summer's suit are cut with skill and precision

The sewn felt and cotton strips are ironed flat

Meanwhile, the vintage paper kites are precisely cut

The edges are folded and glue is applied

The string is inserted along the edges

The string is attached to the wooden frame

The rag tail is tied to the kite

Fall's miniature felt dachshund is sewn together

After sewing, the pups must be turned inside out

Fine stuffing and finishing is required on each dachshund

The dogs come to life with skillful airbrushing

Fall's mohair wig is carefully styled

Dressing begins on the Fall dolls

A group of Fall dolls await final inspection

The Toddler Bears are sewn of Shulte brand mohair plush from Germany

Each bear is artistically airbrushed

Ivy's dress is cut of fine Swiss embroidered cotton

Ivy's dress requires several ironing steps

The Walter bears are readied for dressing

The felt ivy leaves are cut and sewn

After sewing, wire is inserted into each stem

Each ivy leaf is hand painted

The felt leaves are woven into a wreath

The organdy pantaloons are put onto the bears

Walter's adorable linen hat is added to his outfit

Ivy's real pearl buttons are buttoned

Her sash is tied in place

A tray of completed Walter's await boxing

Each bear is beautifully packaged

Ivy gets ready to meet her new owner!

"Puddles" the duck is sewn of fine alpaca plush

After stuffing, the hole is sewn closed

Following molding, the seams are carefully brushed

The felt feet feature heavy wire inserts

Ironing the felt duckling feet

Each foot is artistically airbrushed

The feet are inserted into each duckling

The glass eyes feature felt backing

The tiny umbrella handles are individually molded

Each handle is sanded prior to painting

The handles are attached to the umbrella shafts

So'Wester hat is sewn and topstitched

Each hat is ironed and finished

The tiny custom-made buckles are fastened

The hats and umbrellas are added

The ducklings are packaged for shipment

Each Puddles includes a numbered certificate

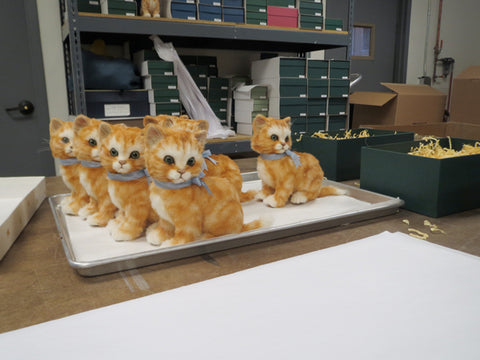

The parts for Marmalade are cut of the finest alpaca plush

The fur is flicked aside by hand to avoid cutting the pile

The kitten bodies are skillfully sewn together

The separate head parts are sewn together

The kittens must then be turned inside out

A sitting kitten begins to appear!

Before stuffing, the brass 'RJW' button is permanently affixed

The neck is shaved where the joint will rotate

The kitten head is molded in the heated press

Molding brings out the sculptural details

The tiny felt paw pads are also molded into shape

A tray of molded felt paw pads

Each paw pad is carefully shaded

The tiny front foot pads are sewn in place

The center pad is also affixed

The Marmalade kittens are artistically airbrushed

Each body and head requires extensive airbrushed markings

The paper weight eyes are inserted

The eyes are positioned in their felt-lined sockets

The kittens are nearing completion

The silk bows are tied around the neck

A Marmalade kitty sits in the workshop window

A group of Marmalade kittens await boxing

The deluxe custom-made boxes are readied

Each Marmalade is nestled for its journey to the Toy Shoppe!

Prior to molding, the Jockey's arms are hand stuffed with kapo

Here is a tray of stuffed and molded feet

The felt costume is slipped onto the Brownie

The felt and leather hat visor is sewn together

The seams are ironed flat inside the Jockey's cap

Gather stitches are sewn for the tiny felt buttons

A tray of completed Jockey caps

The Jockey's leather boot uppers are sewn & topstitched

The boot uppers are prepared for forming

Each boot is hand-cobbled on the metal last

A group of Brownie Jockey's near completion

The candy container bunnies are made of the finest alpaca plush

The removable heads are lined with luxurious jacquard fabric

A tray of airbrushed bunny heads

The delicate whiskers are sewn in place

The parts for the ribbon and flower garlands

Each blossom is handmade out of wool felt

The handmade garlands are woven together

The finished garland is tied around Pansy's neck

The numbered edition tag is sewn to each rabbit

The bunnies are carefully packaged for shipment

The numbered certificate is also included

Each bunny will travel to a different household!

The felt faces are molded in the hydraulic press

The heads are covered in cloth and re-molded

Gesso prepares the 'canvas' for painting

The heads are completely airbrushed

The necks are arranged and tied in place

Hand painting begins in several stages

The eyes are painted in several detailed steps

The nose receives its shock of dark paint

The eyebrows are airbrushed prior to painting

The buckram torsos are wrapped in felt

Trays of molded lower legs await jointing

A tray of jointed felt bodies

The patches are meticulously hand sewn

Each boot is hand cobbled on metal lasts

Scarecrow boots in various stages of completion

A pile of miniature Scarecrow gloves!

The tiny gloves are put on the felt hands

Each hat receives it ragged hatband

The Scarecrow heads near completion

Each head is amazingly consistent

The dolls are dressed

Each doll receives its final airbrushed shading

A group of dolls ready for boxing

Each doll finds its own numbered box

The Scarecrows have taken over the shipping area!

Dorothy's tiny pinafore is sewn together

Dorothy's blouse is sewn of fine Italian organdy

Tiny buttons are sewn to the pinafore

Dorothy's basket is handmade at the RJW workshop

Each basket is meticulously woven out of ash splints

The baskets are incredibly small and detailed!

A small group of completed Dorothy baskets

Silk fabric is sewn for the Ruby Slippers

Each tiny shoe goes through several stages

Dorothy is deciding which shoes to wear!

The Dorothy mice are dressed

Each mouse is given her own basket

A tray of Dorothy mice in process

The mice are beautifully packaged with certificates

The Scarecrow mouses' tunics are sewn together

Several ironing steps are required

A tray of Scarecrow tunics in process

The Scarecrow mice are carefully dressed

A tray of Scarecrow mice in process

The parts for the Tin Man's costume are hand formed

The collars are shaped using a wooden tool

The Tin Man's suit requires several assembly procedures

The Tin Man's tiny funnel hat is hand formed

The miniature axe handles are cut out of basswood

Each handle is carefully sanded

The completed axes are hand painted with silver paint

The Tin Man is dressed for his role!

Each Tin Man receives his axe

he Tin Men are numbered and boxed for shipment

The Cowardly lion's head is hand sewn prior to stuffing

The Cowardly Lion's suit is turned inside out

The mohair costume requires hand-shaving

The Cowardly Lion's mane is gently curled!

A tiny red silk bow is added to each Lion's coiffure

A tray holds all four of the main Oz characters